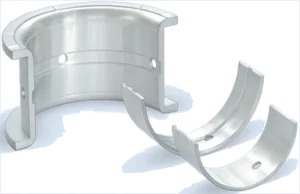

Runner plates play a crucial role in industrial equipment, providing support and protection for rotating components. Over time, these plates can become worn or damaged, compromising equipment performance and posing safety risks. Fortunately, runner plates refurbishment can help businesses restore their equipment to optimal conditions. In this article, we’ll explore the importance of runner plates refurbishment and how it can benefit businesses.

Understanding Runner Plates Refurbishment

Runner plates refurbishment involves the restoration of worn or damaged runner plates to their original condition. The process typically involves cleaning, inspecting, and repairing the plates, followed by re-machining and re-coating. The result is a plate that is as good as new, providing maximum support and protection to the equipment.

Benefits of Runner Plates Refurbishment

Refurbishing runner plates offers several benefits to businesses. Firstly, it extends the lifespan of the plates, reducing the need for frequent replacements. Secondly, it ensures optimal equipment performance, minimizing downtime and maintenance costs. Thirdly, it enhances safety by preventing equipment failures and minimizing the risk of accidents. Finally, it’s more cost-effective than replacing the plates entirely, saving businesses significant amounts of money in the long run.

Types of Equipment that Use Runner Plates

Runner plates are used in various industrial equipment, including turbines, generators, pumps, and compressors. These pieces of equipment are critical to various industries, including power generation, oil and gas, and manufacturing. Maintaining the performance of these machines is essential to ensuring smooth operations and profitability.

Choosing a Runner Plates Refurbishment Provider

When selecting a runner plates refurbishment provider, businesses should consider several factors, including experience, quality of workmanship, turnaround time, and pricing. A reputable provider should have a team of skilled technicians with extensive experience in refurbishing runner plates. They should also use the latest equipment and technology to ensure the highest quality workmanship. Additionally, the provider should offer competitive pricing and fast turnaround times to minimize equipment downtime.

Conclusion:

In conclusion, runner plates refurbishment is an essential process that can benefit businesses in numerous ways. By refurbishing worn or damaged runner plates, businesses can extend the lifespan of their equipment, ensure optimal performance, enhance safety, and save money in the long run. When choosing a runner plates refurbishment provider, businesses should prioritize experience, quality of workmanship, turnaround time, and pricing. By selecting a reputable provider, businesses can enjoy the benefits of runner plates refurbishment and maximize their equipment performance.

For more details stay connected with Citation Links:- zoominfo.com, frasersdirectory.com, rocketreach.co, marinetrac.com, localwork.ca