Why do bearings fail? Sadly, there’s no straightforward answer to this question. Whenever we appraise bearing materials for any applications, we also try to find out why the previous materials may have failed. We take operating states, running temperatures, lubrication problems, and many other factors into consideration in order to find the root cause.

What are the most common causes of bearing malfunction?

Bearing lubrication: Bearings tend to overheat without right lubrication. Which can substantially increase your replacement & safety outlays. The use of wrong lubrication, sub-standard lubrication, or even a total breakdown of the lubrication are the probable cause of lubrication failure. Another challenge that lubricated bearings generally pose is that excessive grease tends to lure dust and other pollutants that can disrupt the service lifecycle.

Temperature: Thicker bearing wall is capable of resisting higher temperature compared to a thin-walled plastic bearing.

Corrosion & contamination: Contaminants like sand, dirt, water, and chemical composites can pose several issues in bearing assemblies. For instance, they are capable of degrading the lubricant or destroying the surfaces of bearing, all of which can make the bearing wear untimely.

Misalignment:

Bent shafts, out-of-square spacers, out-of-square clamping nuts, out-of-square shaft shoulders, and incorrect installation because of loose fits can prompt misalignment, which result in overheating and bearing failure.

How to get rid of bearing failure?

- Choose the correct bearing: The bearing you choose should be correct in size, have low friction, high firmness, and silent run. Bearings supplied by Canadian Babbitt Bearings are engineered to offer high speeds, low noise, excellent service lifecycle, and protection from unfavorable environments and aggressive chemicals.

- Proper installation of bearing: The right tools need to be employed to ensure the bearing installation process is accomplished properly. Manufacturer’s instructions need to be followed for the proper installation of the bearing. Once the installation process is over, it’s necessary to check and confirm that all components are properly aligned and positioned.

- Right lubrication: To make sure the bearing operates productively throughout its entire service cycle you need to apply lubrication as per the guidelines of the manufacturer. It is recommended to apply the right kind of lubricant and use them in the right quantity.

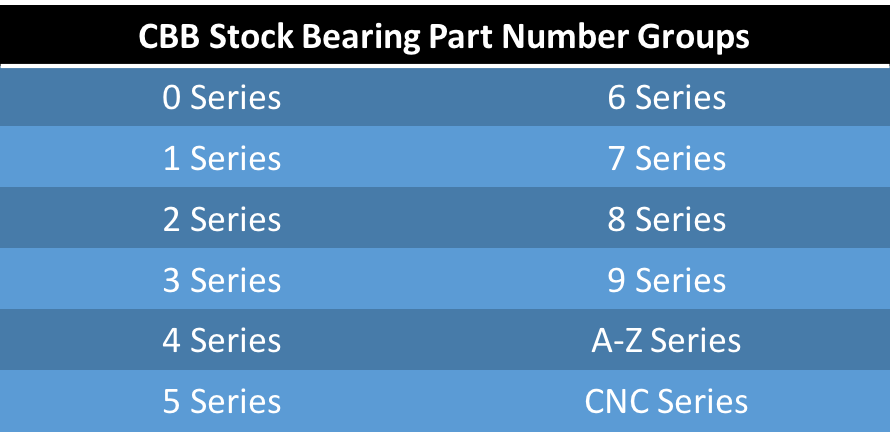

Canadian Babbitt Bearings offers many different types & sizes of bearings including Babbitt, Bronze, Zinc and Stock Bearings of the highest quality. If you need any further assistance regarding stock, bronze, or zinc bearings, feel free to call their customer support team for assistance.